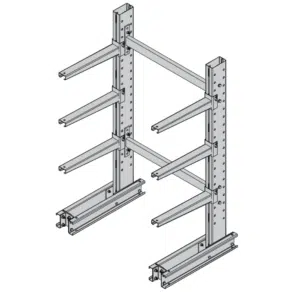

Cantilever rack installation is the process of setting up cantilever racking in a warehouse. Cantilever racking is an industrial storage system with large metal bases, uprights, and cantilever arms. These arms protrude outward to store long, awkwardly-shaped products.

Cantilever is excellent for many applications but requires secure installation before use — it works only when customized for the application and properly installed. We recommend contacting professional pallet rack installers to set up cantilever racking in your warehouse. Before attempting this process, one must equip themselves with the proper tools and knowledge.

What Is Required For a Cantilever Rack?

Cantilever accessories can be added to the system anytime. Arm lips, pipe stops, solid decking, the number and style of arms, cantilever roofs, and more are entirely customizable.

How to Erect a Cantilever Rack System

Installers follow a set of precise processes to erect cantilever racking. It’s crucial to stay organized when installing or tearing down racking. Grouping components by size, type, and capacity helps avoid mixups and keeps the project on schedule. That said, here is our step-by-step process for installing cantilever racking:

- Start by purchasing cantilever racking for your application

- Group components together within the warehouse to stay organized

- Create a clear path in and out of the warehouse during the installation

- Snap a chalk line on the floor to indicate where the front of the rack should align

- Loosely bolt the first and second uprights to the bases and add bracing

- Loosely assemble the next upright before tightening the previous upright

- Continue this process for each upright until the process is complete

- Tighten all bolts to form snug-fit connections

- Anchor bases to the floor

- Attach arms and accessories to the system

- Begin storing your products!

Pallet Rack Anchoring

One common question we get asked is if cantilever racking needs to be bolted down. The answer is a resounding “yes”. Use a minimum of two ½” x 4¼” anchors, one on each end of the base, to secure your cantilever system.

Anchoring is an essential step that strengthens your cantilever racks, improves your warehouse’s working conditions, and prevents future accidents. Anchors and all bolted connections must be inspected once a year, and any damaged components must be replaced immediately.

Be sure to follow proper loading and unloading practices to avoid placing unnecessary strain on your cantilever system and to prevent damaged components.

Dangers of Improper Cantilever Rack Installation

Cantilever racks can hold massive amounts of weight. The capacity capabilities of cantilever racking come from the heavy materials used in manufacturing. Industrial steel racking is incredibly difficult to handle and requires professional design and installation.

At Cantilever Rack Now, we offer various cantilever sizes with different capacity ratings to meet your needs. Below are some of the risks of improper cantilever components and installation.

Cantilever Rack Damage

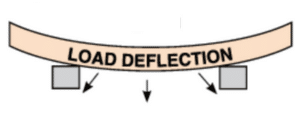

Cantilever rack damage is typical in improperly installed or designed systems. Cantilever beam deflection is one form of damage that results from bad design and loading practices. Cantilever beams are most likely to fail when they are repeatedly overloaded or if the product is placed closer to the end of the arms than the uprights.

Fixing a damaged cantilever system or component is unwise – damaged parts lose their structural integrity, and complete restoration is an impossibility. We suggest replacing damaged cantilever components immediately to avoid total cantilever rack failure, personal injury, or death.

Load Deflection

To prevent load deflection, preemptively test your product on wooden blocks (representing cantilever arms) to determine how close to place your cantilever arms. Please note: products should overhang the first and last arms in a run by half the distance between uprights.

Cantilever Rack Failure

A substantial risk of improper installation is total cantilever system failure. Many things can cause cantilever failure, but improper installation should never be one of them. Here are some things that cause cantilever rack failure:

- Improper installation

- Overloading the arms

- Improper loading practices

- Forklift damage

- Insufficient capacity ratings for the storage at hand

Personal Injury or Death

When it comes to cantilever rack installation, the most significant risk is personal injury or death. Inventory loss can be devastating from a business perspective, but inventory and racking can be replaced – a human’s life cannot.

Start at the source. As a business owner, you are responsible for overseeing the safety of your employees. Proper cantilever installation is something you can control from the very start.

Cantilever Rack Installation Experts

We are well-versed in cantilever racking specifications and installation processes at Cantilever Rack Now. We would be happy to connect you with professional pallet rack installers and answer your questions about cantilever rack installation. Call 888-680-2256 or fill out our online quote form to get in touch with an expert today!