What is Cantilever Beam Deflection?

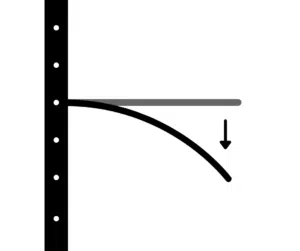

Deflection for a cantilever beam is the gradual downward bending of cantilever beams (also known as “arms”) under heavy loads. A small amount of cantilever beam deflection is average, but too much threatens the rack system and its structural viability.

Bending cantilever beams create a hazardous work and storage environment. Warehouse managers are responsible for regularly inspecting all cantilever rack systems, calculating deflection, and purchasing replacement arms as needed.

Cantilever Rack Now supplies cantilever rack components and designs entire storage systems for warehouses nationwide. Call 888-680-2256 or fill out an online quote form to speak with a cantilever rack specialist today!

When Does Cantilever Beam Deflection Occur? Cantilever Dos and Don’ts

Cantilever arms deflect under loads too heavy for the arm’s capacity rating. Improper loading techniques can also cause arms to deflect or other damage to occur. Improper loading includes point loads and overloading.

Point loads (also called tip loads and end loads) are placed at the end of the cantilever arm, not centered or near the upright. Point loading causes unnecessary stress concentration on cantilever arms and may result in cantilever beam deflection where the ends of the arms bend downward.

Overloading is storing more weight on a cantilever arm than intended. Some arms have higher storage capacities to handle heavier loads. Low-capacity arms must be properly loaded with the right amount of product to avoid overloading and deflection.

5 Tips to Avoid Cantilever Beam Deflection:

Brace set length

Each arm should carry equal weight. Cantilever beams must be equally spaced for the product to achieve equal distribution across arms. Cantilever brace sets determine arm spacing, so choosing the right brace set length is vital to prevent cantilever arm or load deflection.

Choose the right arms

There are three factors to choosing the right cantilever arms: Arm length, arm capacity, and arm pitch.

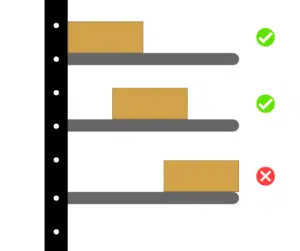

The arm length should match the size of the load. If the load overhangs the end of the arms, it is incorrectly stored and may lead to deflection.

The arm capacity should meet or exceed the capacity being stored. When choosing cantilever arms, always refer back to the heaviest load and possibly slightly heavier to be safe.

Choose between straight and inclined arms depending on the product stored. If the product is cylindrical and at risk of rolling forward, inclined arms will work best.

Properly load the arms

Cantilever loading is crucial for preventing cantilever beam deflection. Load slowly to avoid shock loads. Shock loads occur when the load is dropped suddenly onto the arms and can cause arm damage and deflection.

Center the product on the arm or as close to the upright as possible to achieve a uniformly distributed load (UDL). Point loads occur when the product is placed too close to the end of the cantilever arm and can cause deflection. Evenly distributing loads is standard practice and the best strategy to extend arm life.

Leave horizontal overhang

Although overhanging off the ends of the arms is improper practice, there is a good type of overhang that allows equal weight distribution between arms. It is essential to enable overhang to the left and right off the first and last arms. This allows each arm to support equal weight without putting more strain on any one arm (particularly the first and last).

The proper amount of overhang is determined by the distance between arms. It is recommended that the load be distributed so that 25% of the load overhangs each side. Another factor that determines overhang is how rigid the load is.

Implement forklift training

Good lift truck drivers will follow responsible forklift principles. Ensure every certified lift truck driver is extensively trained and screened with ongoing quality checks. Forklifts are the primary cause of pallet rack damage and cantilever arm damage.

Leaving at least 6” of vertical lift clearance between the top of the product and the next arm allows forklift drivers to safely load and unload the racking.

Allowable Deflection for Cantilever Beams

Cantilever racking has some percentage of allowable deflection. Deflection is usual under heavy loads, but only to a certain degree. All cantilever arms are manufactured with at least a 2-degree pitch – this is to compensate for deflection. When fully loaded, the arm should never bend lower than parallel to the cantilever base.

You must know your storage system’s limit by calculating allowable deflection.

How to Calculate the Deflection of a Cantilever Beam

To calculate the deflection of a cantilever beam, place a level on the outstretched beam. The level should never read less than plumb (or level with the base of the cantilever system). A downturned cantilever arm signifies a dangerous level of deflection and should be replaced immediately.

Another sure way to calculate cantilever beam deflection is to measure the angle where the arm meets the cantilever upright. The arm, fully loaded, should never be less than parallel to the base – or less than 90 degrees. If the angle is less than 90 degrees, replace the arm immediately with a higher-capacity alternative. If an arm is less than parallel to the ground, the load could slide off onto the ground, causing damage, personal injury, or death.

Cantilever Arm Replacement

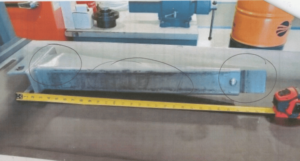

Have your cantilever arms been damaged or deflected past the allowable limit? In the image to the right, the cantilever arm has sustained damage from deflection, including a warped end connector, arm damage, and bent arm lip. Cantilever Rack Now offers replacement cantilever arms for scenarios like this.

For help choosing replacement arms, call CRN at 888-680-2256. We happily answer any questions and help bolster storage systems with new parts.